ΚΑΘΗΜΕΡΙΝΕΣ 07:30 - 16:00

ΣΑΒΒΑΤΟ ΚΛΕΙΣΤΑ

ΒΡΕΙΤΕ ΜΑΣ ΣΤΟΝ ΠΕΙΡΑΙΑ

ΑΙΤΩΛΙΚΟΥ 34-36 ΚΑΙ ΣΦΑΚΤΗΡΙΑΣ 11

Aristo Mig 4004i Pulse Aristo Feed 3004, U6/U8 Aristo YardFeed 2000, U6XA00166520 Low weight multi process inverter equipment |

Aristo® Mig 4004i Pulse is an electronic controlled MIG/MAG/MMA lightweight inverter based welding power source, designed for high productivity and quality welding applications.

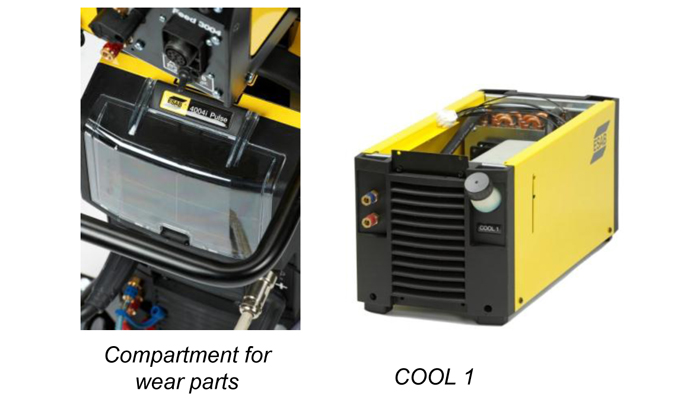

The floor space (footprint) and the weight are reduced by 70% compared to conventional equipment. The new compact design combined with inverter technology has made Aristo® 4004i Pulse truly transportable. Fan on demand cooling systems increase the welding time of the equipment. The cooling unit COOL 1 provides cooling of liquid-cooled torches to support great comfort to the welder. The cooling fans in the power source and the cooling system for the torch automatically turn off after 6.5 minutes inactivity, significantly reducing the idle time energy consumption.

This 4th generation inverter offers considerable improved efficiency with a power factor better than 0.95. This gives you minimized energy consumption and will offer significant reductions in your energy cost with the same welding conditions.

Technology Weight Efficiency

Chopper >149 kg <70%

Inverter 46 kg >85%

Applications

• Highly productive MIG/MAG welding

• Advanced MMA welding

• Typical market segments:

- General Industrial Fabrication

- Energy Generation

- Windmills

- Trucks Busses and Trailers

- Trains & Railway Cars

- Earthmoving and Mining Equipment

- Mobile Machinery

- Steel Sections

- Shipbuilding/Offshore

• High Duty Cycle – suitable for long runs

• Wide mains input tolerance: 380 - 440 V +/- 10%

• Generator compatible – for on site use

• Standby Function – energy saving system

• Pre-programmed synergic lines to ensure optimum settings with a wide choice of materials, wire dimensions and gas combinations

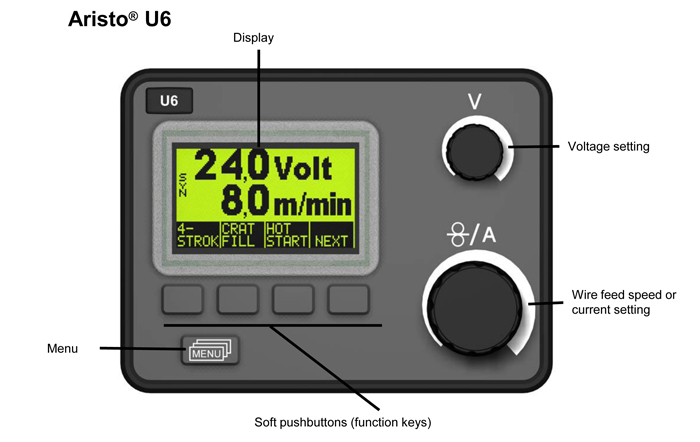

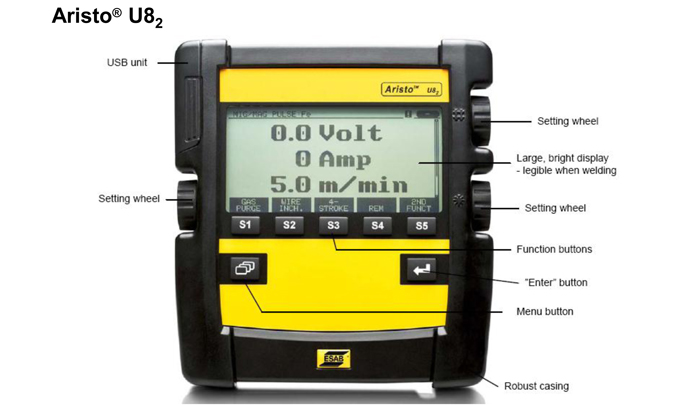

•Memory for 10 (U6) or 255 (U82) welding schedules

•Customized synergic lines (U82)

•SuperPulse™, the welding process with the ability to control the heat input (U82)

• QSet™ – Intelligent welding system

•Creep start, gas pre-flow and hot start provide a soft and more direct start with less spatter

•Crater filling, adjustable burn-back time and post gas replace a smooth finish, extend the lifetime of the contact tip and guarantee no cracks at the end

•TrueArcVoltage™ (valid only in combination with the PSF torch range) measures the correct arc voltage value independent of length of the interconnection cable, return cable or welding torch assembly.

QSet™ - The intelligence welding system which simplifies welding

QSet™ monitors the welding arc and optimizes welding parameters in dip transfer, just weld and the arc condition will be optimized within a few seconds. Then simply adjust the wire feed speed to suit the application and let QSet™ do the rest.

A robust fully enclosed design protects the welding wire from moisture, dust and other airborne contaminants.

Aristo® Feed 3004 is available with 2 operational solutions, the U6 panel and the U82 pendant.

A 7.5 m connection cable to provide a wider working range is available for the U82 pendant. Access for remote controls at the front of the feeder.

Adapter kit for PSF RS3 torches and MXH Push-Pull guns provide access to pre-programmed welding schedules from the torch (PSF RS3) or control of the wire feed speed from the PP guns (MXH 300/400w PP).

The feeder accept standard 200, 300 and 440 mm spools additional to MarathonPac™.

LiveTig™

The LiveTig™ start function that electronically limit the start current by 12-15A is implemented to U6 and U82.

Aristo® Mig 4004i Pulse combined with U6 or U82 offer a complete multi-process package supporting MMA, TIG, MIG/MAG and pulse MIG.

The package support welding of mild steel and stainless steel in all processes and Aluminium in MMA, MIG/MAG and pulse MIG.

SuperPulse™

SuperPulse™ (U82) is the optimum MIG/MAG process for control of the heat input or bridging of variable gaps.

Aristo® Feed 3004 U6 and MXH 400w PP

Technical data Aristo® Mig 4004i Pulse

Mains supply, V/Hz 380–440, 3~50/60

Mains cable, Ø mm2 4 x 4

Fuse, anti surge, A 20

Permissible load at MIG/MAG

100% duty cycle A/V 300/29

60% duty cycle A/V 400/34

Setting range A

MIG/MAG 16-400

MMA 16-400 TIG (LiveTIG) 4-400

Open circuit voltage, V 55

Open circuit voltage VRD, V < 35

Idle power, W 40

Efficiency at max current, % 88

Power factor at max current 0.94

Dimensions L x W x H, mm 610 x 250 x 445

Weight, Kg 44.5

Incl COOL 1 excl. coolant, Kg 58

Operating temperature, °C -10 to +40

Enclosure class IP23

Application class S

Insulation class H

Certification CE

Technical data, Water cooler COOL 1

Power supply, from power source, VDC 24

Coolant flow capacity, l/min 2.0

Coolant quantity, l 4.5

Cooling power, kW 1.3

Max pressure, bar 4.5

Max pressure height to torch, m 8.5

Weight / incl. coolant, kg 12 / 16.5

Dimensions incl. filler tube L x W x H, mm 610 x 256 x 256

Technical data, Aristo® Feed 3004

Power supply, AC 42

Wire spool capacity, kg 18 (30**)

Max. spool diameter, mm 300 (440**)

Wire feed speed, m/min 0.8-25.0

Dimension L x W x H, mm 690 x 275 x 420

Weight, kg 15

Copyright © 2025 Emporiki - Group

Powered by WEbdEC